Do you want to know the craftsmanship of crocodile leather? Why is HERMES' crocodile skin so fascinating? Take you into the world of crocodile leather

Do you want to know the craftsmanship of crocodile leather? Why is HERMES' crocodile skin so fascinating? Take you into the world of crocodile leather

All crocodile leather and rare animal leather of FOBO comply with international endangered animal regulations and are legally imported under the CITES Convention.

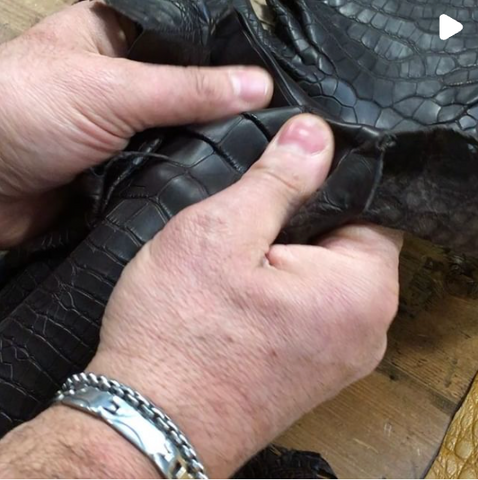

Introduction of crocodile leather tanning technology:

Crocodile leather tanning technology introduction: agate stone polishing technology, matte technology, waxed leather technology, nappa technology, Himalayan technology, blue dyeing technology, chrome-free tanning technology, frosting technology, film technology, multiple dyeing technology and so on.

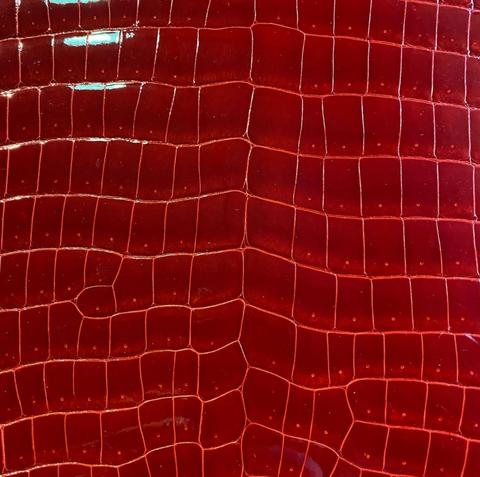

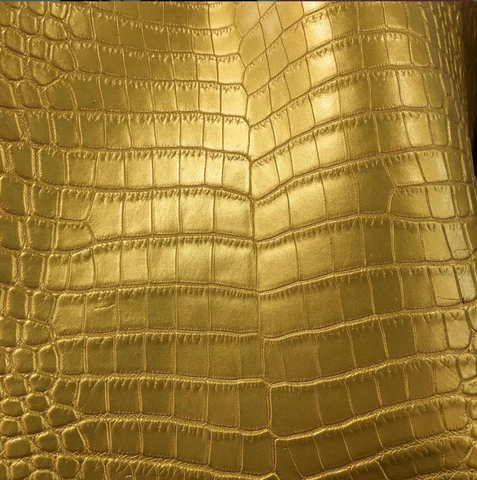

Agate Stone Polishing Process: One of the typical alligator finishing methods, which imparts smooth, elegant and jewel-like luster to the leather surface. After dyeing, the surface of the alligator leather is coated with a protein-based polish such as casein in a clean room, and a strong rubbing is applied with agate stone to create a mirror-like sheen.

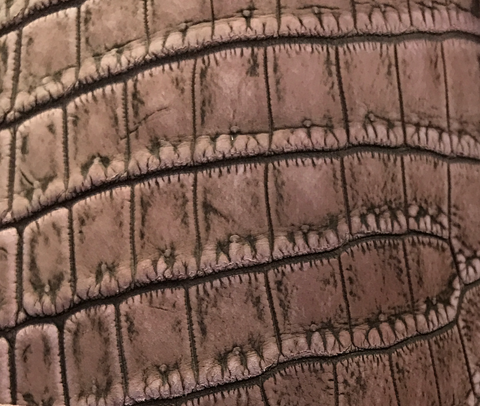

Matte finish: It is developed by improving farming techniques and tanning techniques. When dyeing, the leather is oiled to make it soft and moderately tensioned, and the leather surface is polished with a felt polisher during finishing to give it a soft sheen. Because of its soft and low-gloss finish, it can be used in a wide range of styles from dress-up to casual. In addition, the finish allows you to enjoy the feeling of use (change over time), such as increasing the depth of the color and gradually increasing the gloss.

Waxed Leather Process: After dyeing in a roller, wax is pumped into the leather to cover the surface. Like the matte finish, the felt finish provides a moderate sheen. Crocodile leather can look wild and random and become extra attractive over time.

Nappa Craft: A soft finish specially developed for garments and gloves. A large amount of softener is added when tanning crocodile leather, but as the amount increases, the weight increases proportionally. FOBO pursued the tanning process to express a light and silky touch "fluff that makes you want to touch" and finished with the ultimate nappa finish.

Himalayan Craft: This is a relatively new technique with a beautiful finish that resembles the snow-capped Himalayan mountains. Typically, chrome tanning is used in crocodile tanning, but it is not suitable for pure white because it is a bluish chemical. In the Himalayan finish, chrome tanning agents are not used for tanning, but the original natural pattern of the crocodile is used. Since the finishing starts without dyeing, the raw leather to be used must be chosen carefully, not only for quality, but also for density of grain pattern and balanced symmetrical decor.

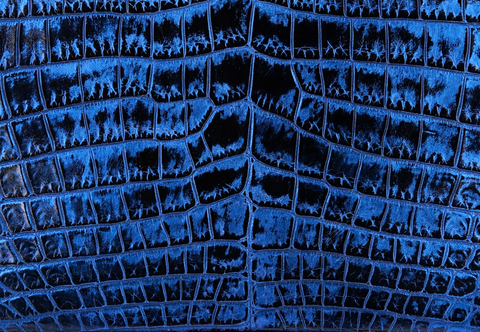

Indigo dyeing process: Indigo dyeing is an ancient dyeing method using an indigo plant also known as indigo . Typically, leather is batch dyed with acid dyes on a drum. On the other hand, indigo dyeing is done by hand using natural indigo dyeing. Indigo dye changes color when it comes into contact with air, but instead of a single dye, it deepens with repeated dyeing. FOBO's research uses crocodile skin to express traditional skills, and successfully restores the most beautiful colors of nature that are about to be lost.

Chrome-free tanning process: Chrome tanning is a good method of tanning, but it is not suitable for making leather into light or pastel colors because chrome can give leather a bluish tint. FOBO research has developed a chrome-free tanning formulation so that we can produce high-quality chrome-free leather. "Chrome-free tanning" gives the skin a translucent, white appearance without the natural dark texture of crocodile leather. Another method is to use vegetable tanning, using plant tannins to process crocodile skin, the base will be lighter skin color.

Grinding process: The surface of the crocodile leather is polished with abrasive cloth, which requires skilled masters to operate to avoid damage to the crocodile leather.

Film process: heat and apply pressure to the film, and stick it on the crocodile skin

Multiple dyeing process: It is made by spraying or brushing, dyeing, hand painting, scraping, etc. First, use the base color as a primer and then use color stacking to make beautiful colors.